The flatbed vs dry van choice is, after all, not one of the easiest and most misunderstood options to make by truck drivers, transporters, and customers in the shipping sector. Both types of trailers travel with tens of thousands of shipments every year, but, they are designed for particular loading methods.

The decision on which one to use depends not on preference only but on cargo protection needs, loading freedom, weight limit, cost factors, and the required freight handling from origin to destination.

Selecting the appropriate trailer can also lower the handling costs, decrease the risk of cargo theft or loss, or make the loading and unloading processes easier. This choice is right if it not only simplifies work but also maintains freight safety and enhances overall transportation performance.

Defining the Types of Trailers

In order to perform the comparison of the two previously mentioned types of trailers, you need to first know the traits that differentiate them. The dry van trailer is essentially a sealed box that is totally covered. It protects the cargo from weather, road debris, and access by unauthorized individuals. This is the most prevalent type of freight trailer used for long-distance trips by trucks. A flatbed is an open space that is free of walls or a roof. These definitions align with standard terminology used across the U.S. trucking industry, including those outlined in the American trucking glossary. [Wikipedia – Glossary of the American trucking industry]

This type of trailer allows cargo to be loaded from the sides, rear, or top. It also accommodates oversized or irregular freight that cannot fit into enclosed trailer dimensions.

The Main Discrepancies at a Glance

| Feature | Dry Van | Flatbed |

| Cargo protection | Fully enclosed | Exposed, requires tarping |

| Loading methods | Rear loading only | Side, rear, and top loading |

| Cargo size limits | Restricted by trailer dimensions | Supports oversized freight |

| Cargo security | High by default | Relies on securement |

| Weather sensitivity | Minimal | High |

| Common freight | Pallets, boxed goods | Steel, lumber, machinery |

This simple comparison sparks trailers’ essence that is somehow inextricably linked to the cargo condition. DRY VAN VS FLATBED: Which is BETTER?

Because of that reason, flatbeds are perfect for construction materials, industrial equipment, and freight that cannot be palletized.

EXPOSED! DIFFERENCES BETWEEN FLATBED AND DRY VAN TRUCKING!

Dry Van Restrictions

Dry vans must have:

- Dock or forklift loading from the rear

- Standardized pallet or box configurations

- Freight that fits within fixed trailer dimensions

Though restrictive, this standardization actually eases shipping operations.

Weight Capacity and Trailer Dimensions

| Factor | Dry Van | Flatbed |

| Typical length | 53 ft | 48–53 ft |

| Interior height | ~110 in | No height limit |

| Width | ~102 in | ~102 in |

| Practical weight use | Evenly distributed | Highly flexible |

Length and height are the extra dimensions that flatbeds offer while dry vans get regulated by internal standards that augur a more even weight distribution.

Cost Considerations and Shipping Costs

Choosing the type of trailer directly impacts shipping costs. Dry van costs are generally characterized by lower base rates, faster loading at standard docks, and less labor-intensive cargo handling, which makes dry vans cost-effective for high-volume, standardized freight. Flatbed costs, by contrast, are typically higher due to specialized handling requirements, longer loading and unloading times, and increased responsibility and risk for the carrier and driver. However, flatbeds often move freight that dry vans simply cannot accommodate, making the higher cost unavoidable rather than optional.

Shipping Needs and Transportation Options

The trailer types that are to be compared must be first and foremost influenced by your shipping requirements (flatbed vs dry van). Use a dry van besides protection from weather, cargo is palletized or boxed, and security and consistency matter most if freight. Use a flatbed if the reasoning is that the cargo is bigger or irregular, side or top loading is needed, and the freight does not fit standard enclosures. The differentiation of the operations of flatbed and dry van trailers is not limited to the trailers only. Flatbed operations require more physical strength, higher accountability for cargo securing, and a bigger exposure to rain when loading. Dry van operations are associated with quicker turnarounds, less manual labor, and a more regular quality of freight. This difference is the one that affects the driver’s choice, the requirements for training, and the long-term work. No trailer type inherently has an upper hand over the other. The exact option relies on how the cargo is handled, the shipper’s expectations for cargo security, transportation means available, as well as cost and operational limit. The flatbed versus dry van dilemma is not about who is the best – it is all about the compatibility between the plain cargo and freight.

Final Remarks

Opting for either flatbed or dry van freight trailers signifies a thoughtful and strategic decision rather than a habitual act. An understanding of the needs of cargo regarding protection, loading methods, weight capacity, and shipping costs, empowers carriers and shippers to accurately select the right trailer for each task.

Particularly in freight transportation, efficiency is obtained through the right fit of the trailer to the cargo, and not by forcing the cargo to fit into the trailer.

A practical trailer comparison is beyond technical specifications. The decision of flatbed or dry van between these two trailer types must be made due to real loading sites, delivery limitations, and the type of cargo interaction required the route.

Dry vans offer the best transport in environments such as distribution centers, warehouses, and retail docks, where freight goes through standardized processes. On the flip side, flatbeds are often used when shipments are coming from construction sites, manufacturing yards, or outdoor facilities where dock access is limited or unavailable (flatbed vs dry van).

This point shows that the selection of the right trailer does not depend solely on cargo type but also on how and where the cargo joins and leaves the supply chain.

A right trailer comparison is always based on operational reality, not only on equipment capability.

The clear distinction of loading flexibility is the factor that thoroughly differentiates flatbed and dry van trailers.

Being able to load into the side, rear, and top makes flatbeds ideal for transporting cargo which differs in shape, length, and method of handling. The ability to operate this way decreases the risk of encountering limitations during the pickup and delivery process especially with the involvement of cranes or unconventional loading tools.

On the other hand, dry van trailers choose the path of stability by eschewing flexibility. Loading from the rear only and standardized freight dimensions enhance efficiency, minimize variability, and promote faster turnaround times in organized shipping environments.

Indeed to underline this the loading flexibility helps the irregular freight while the operational stability benefits the repeatable, high-volume shipments. Adaptability or predictability value the shipment based on whether it is the former or the latter that carries more value.

Cargo security is an essential factor for trailer selection and risk management

Dry vans are a type of cargo enclosures that protect goods from exterior forces. During the entire trip, the freight is unexposed to weather, road elements, and outside intruders, as long as it is properly sealed. Hence, it is very common for dry vans to be used in consumer products, electronics, and other goods where surface condition and theft prevention are the main concerns.

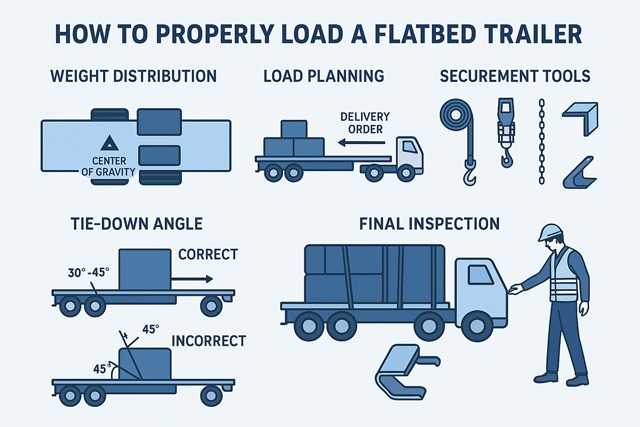

Flatbed cargo security, in contrast, is instead of being passive it is active. It operates through the drivers methods of securing the cargo, knowledge and experience, and periodic inspections.

Flatbeds, even though they allow the freight to be affected by the surrounding conditions, give the driver’s control over the size or weight of the load which cannot be properly secured in a closed manner.

Having the knowledge of the difference between the enclosed protection and securement-based protection allows the carriers to correspond the selected trailer to the right level of risk.

Cost factors are not limited only to the basic freight prices. They also include broader cost considerations, such as the amount of time and labor required for loading, the type of equipment involved, and the potential level of operational risk during transit.

When it comes to loading and unloading standardized freight, the dry van remains the fastest and most economical option. It is considered low-investment equipment because it requires no additional securement and integrates easily into common transportation options like warehouses, distribution centers, and retail docks.

Flatbed trailers, while often more expensive to operate, expand transportation options significantly by allowing carriers to move loads that dry vans cannot handle — especially oversized, irregular, or non-conforming cargo.

Before you commit to a lane or a niche, it helps to understand how cargo and trailer type affect stress, pay, and routine. This breakdown of flatbed vs dry van makes the choice much clearer for beginners.

FAQ

What is the main difference between flatbed and dry van trailers?

The main point of disparity is how the cargo is being dealt with and its protection. For dry vans, it is all about closed protection and stacking in a certain way, while flatbeds are all about the flexibility of being loaded in any way and having the possibility of holding secure themselves the equipment needed for oversized or irregular freight.

Which trailer type presents good cargo security?

Dry vans offer goods cargo security through closure and sealing, thus they are the preferred option for theft-sensitive or weather-sensitive items. Flatbeds are based on active cargo securement, whereby protection is obtained through straps, chains, tarps as well as driver skills.

How does loading flexibility affect trailer choice?

Loading flexibility takes precedence during times when freight can’t be palletized or has to be side or top loaded. Flatbeds feature cranes, open yards, or special loading tools as their main advantages, while dry vans stick to dock-based, standardized operations.

Are flatbeds more expensive than dry vans in every case?

Flatbeds face higher operational costs generally because of labor, securement duration, and the risk of exposure. Still, those extra costs are justifiable in cases when moving cargo that dry vans would not be able to hold due to safety or physical concerns.

Should trailer choice be determined only by the type of cargo?

Correct no. Besides the type of cargo, trailer selection must also consider loading and delivery conditions, loading infrastructure, and trucking routes. The right kind of trailer corresponds to the cargo’s needs and the actual working conditions of the operation, rather than just technical specifications.

In which ways does the transport environment sway the decision between flatbed and dry van?

Transportation environments are the main determinants in the selection of trailers. For example, places such as plants with docks, access control, and predetermined work processes usually prefer dry vans, while construction sites, manufacturing yards, and outdoor locations typically use flatbeds since they lack access to docks and require different loading methods.